Lithrone GX40RP &

GX44RP advance

KOMORI'S MOST EFFICIENT DEDICATED TWO-SIDED PRINTING PRESS

The award winning GLX40RP & GLX44RP press platform, now with Komori's advance feature package, is a truly unique dedicated two-sided press design with many advantages. As a dedicated two-sided press, the RP advance uses a straight through sheet path that does not flip the sheet to perfect.

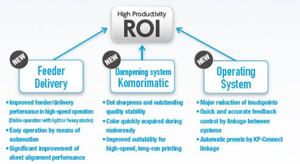

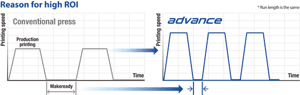

World-class ROI

Komori’s Lithrone advance series takes offset print production to the next level

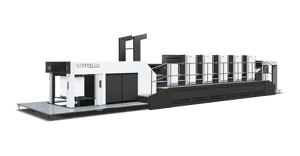

A Unique Technology for High Production Packaging Printing

It is well suited for packaging and has great application for cards, inserts and other heavy stock products. It is built for incredible productivity with high print quality, short makeready, versatile and reliable feeding and delivering, and energy savings. The Lithrone G44 advance is a new strategic press allowing PSP's to provide new added value, staying competitive in a changing print industry.

World Class ROI

The Lithrone GX/G advance series have been developed to provide customers with a world class ROI, with the highly advanced Lithrone sheetfed offset presses.

Connected Automation

Connected Automation, Komori’s concept for creating a Smart Factory, develops labour and work saving solutions, and strengthening standardization and inspection mechanisms.

Print Quality

The optimized dampening system, the dot quality sharpness and stability is maintained while suitability for high speed/long run printing is improved.

Mono Clouds

Features

- Print room operating status can be checked in real-time, even when off-site

- Operators can grasp the progress of connected processes and status of important materials such as plates and paper, for more efficient makeready

- Automatically create a variety of reports, using actual results data, helping to improve productivity

- Shifting from legacy methods (such as job tickets and telephone contact) to digitalization greatly reduces time spent on process management

- Automatically schedule optimal job order with less time spent on makeready and arrangements, for instance by prioritizing fast turnaround jobs or grouping together jobs that use the same ink

Specifications

| Number of colors | 2-12 |

| Maximum print speed (40RP / 44RP) | 18,000 sph / 15,000 sph |

| Maximum sheet size (40RP / 44RP) | 29.5" x 41.3" / 33.1" x 45.3" |

| Minimum sheet size (40RP / 44RP) | 14.2" x 20.5" / 18.1" x 24.4" |

| Thin sheet application range | 0.0016" - 0.020" |

| Thick sheet application range | 0.008" - 32pt |

| Feeder Pile Height | 1,850 (72.8") |

| Delivery Pile Height (40RP / 44RP) | 1,450 (55.1") / 1,250 (49.2) |

Product Brochures