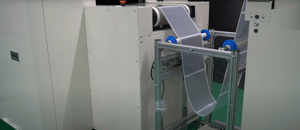

RYURONE 35SZ

Gapless Synchronized Screen-Printing Machine

Position Accuracy

Improving printing position accuracy because the gap between stencil and substrate does not cause plate distortion.

In-plane Uniformity

Stable stencil peel-off angle and amount realize uniform pattern shape on the surface. without fluctuation of printing pressure.

Resolution

Continuous stable printing of thin lines is possible which was difficult to achieve with conventional screen printing.

.jpg?width=300&name=seriaryurone35sz%20(1).jpg)

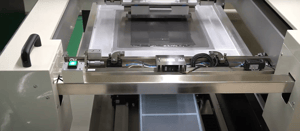

Features

Electronic component-manufacturing technology

- Roll-to-roll manufacturing of MLCCs

- Gapless alignment technology

- Less Bleeding, Resolution and non-defective rate improvement due to consecutive and stable Peel-off printing

- High printing accuracy and repeatability by tension cut on printing

- Less work damage by surface non-touch loading

World’s first! Gap 0 (cylinder synchronous type) screen printing machine

- High printing resolution by screen peel off mechanism (makes fine printing uniformity)

- Printing position accuracy, repeatability and stability (high precision printing)

- Achieve high precision printing repeatability by screen stress free mechanism makes durability + anti-bleeding

Product Brochures

Specifications

| Base Material | Material | Film / Green Sheet |

| Width | 250〜350 mm | |

| Thickness Range | 25〜100µm | |

| Roll Max. Winding Size | φ600 mm | |

| Roll Max. Weight | Approx. 120 kg or Less | |

| Base Material Axis | Unwinding Axis | 3 inches Air Shaft |

| Frame | Size | 750 x 750 〜 800 x 800 mm |

| Print Size | Size | 230 x 230 〜 330 x 330 mm |

| Min. Print Pitch | 10 mm | |

| SQ. Pressure | 0.1〜0.5 MPa (10〜50 kg) | |

| Printing / Coating Speed | 50〜800 mm/sec |

.jpg?width=300&name=seriasvm6151ip%20(1).jpg)