PEPIO F6/F12/F15

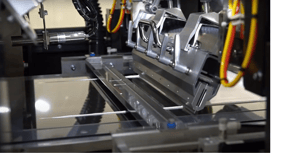

Semi-Automatic Gravure Off Set Printing Machine

Present for R&Dby operability and user friendly set up design

Achieve tohigh accuracy printing by high pression design

Possible to customizefor inline

.jpg?width=300&name=seriapepiof6-f15%20(2).jpg)

Features

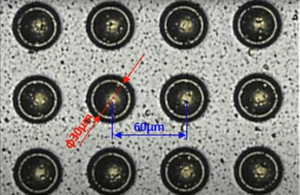

Fine wiring technology

- Semiconductor package manufacturing

- High precision/fine wiring bump formation

- Line & space = 20 µm, realize printing Min. line width 5 µm

- Realize Min. Diameter φ10 µm dot printing

- Printing size accuracy less than ± 5 µm (under 300×300 mm)

Specifications

| PEPIO F6 | PEPIO F15 | |

| Max. Work Size (TD×MD) | (TD)160×(MD)160 mm | (TD)380×(MD)380 mm |

| Work Thickness | 0.05〜2.0 mm | |

| Max. glass plate size (TD×MD) | (TD)200×(MD)260 t=5 mm | (TD)420×(MD)500 t=5 mm |

| Printing (offset / process) Direction | Right→Left(sight from Operation Side) | |

| Worktable | With Alignment Function | |

| Work Fixing Method | Fix by vacuum pump | |

| Vacuum Area (TD×MD) | (TD)150×(MD)150 mm | (TD)370×(MD)370 mm |

| Vacuum Hole Diameter / Pitch | φ0.8 mm /10 mm | |

| Offset speed | 2〜200 mm/s (Parameter Setting) | |

| Alignment Adjustment Camera | CCD Camera 2 units | |

| Camera view range | Approx. 6×6 mm | |

| Work Distance | Approx. 170 mm | |

| Plate (Screen) Table Fixing Method | Fix by vacuum | |

| Vacuum Area (TD×MD) | (TD)190×(MD)250 mm | (TD)410×(MD)490 mm |

| Vacuum Hole Diameter / Pitch | φ2.0 mm /10 mm | |

| Offset speed | 2.0〜200.0 mm/s (Parameter Setting) 0.1 mm/s (unit) | |

| Table Speed during Coat / Print | 2.0〜200.0 mm/s (Parameter Setting) 0.1 mm/s (unit) | |

| Blanket Cylinder Ref. diameter | φ190 mm | |

| Blanket treatment | t=2.0〜3.0 mm (Including Under Blanket) | t=0.5〜3.0 mm (Including Under Blanket) |

| Printing pressure (Cylinder pos. setting) | 0.000〜0.250µm (Parameter Setting) | |

| Rotation Speed Ratio (to work / plate) | -0.20 〜 +0.20% (Parameter Setting) | -0.500 〜 +0.500% (Parameter Setting) |

| Machine Dimensions(W×D×H) | (W)1859×(D)1404×(H)2047 mm | (W)2910×(D)1230×(H)1805 mm |

| Machine Weight | Approx. 1600 kg | Approx. 3500 kg |

| Power Supply | 3-Phase 200V 50/60Hz 6.9kW | |

| Air Supply | 30Litter/min 0.5MPa | |

| [TD: 90° for printing direction / MD: Printing direction] | ||

| Auto 0 Point Setting | : Automatic |

| Anti-static bar | : Blanket Cylinder near rear side of printing |

| Dryer unit for blanket | : IR /Heat circulation |

| Ink dispenser | : Ink dispenser (Pumping) |

| Blanket cleaner | |

| Full Frame Cover | : Without HEPA Filter |

.jpg?width=300&name=seriasvm6151ip%20(1).jpg)

.jpg?width=300&name=seriaryurone35sz%20(1).jpg)